Simple dry mortar production line CRM3

Product Detail

Introduction

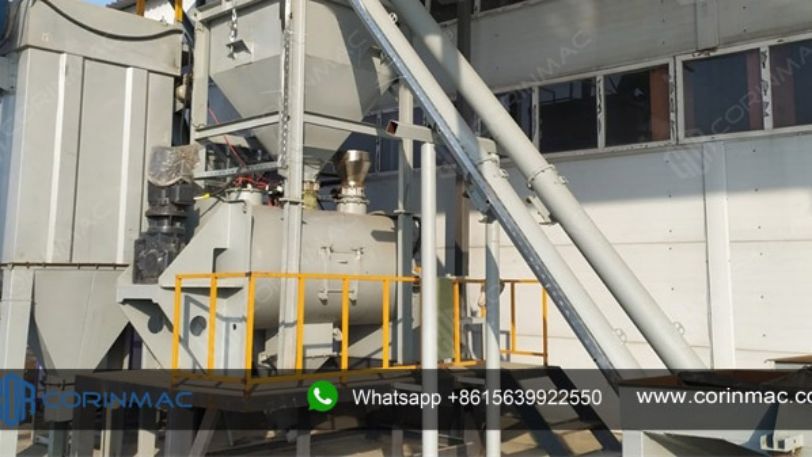

Simple dry mortar production line CRM3

The simple production line is suitable for the production of dry mortar, putty powder, plastering mortar, skim coat and other powder products. The whole set of equipment has double mixers that run at the same time which will double the capacity. There is a variety of raw material storage equipment is optional, such as ton bag unloader, sand hopper, etc., which are convenient and flexible to configure. The production line adopts automatic weighing and batching of ingredients. And the whole line can realize automatic control and reduce labor cost.

Dry mortar mixer

The dry mortar mixer is the core equipment of the dryh mortar production line, which determines the quality of the mortars. Different mortar mixers can be used according to different types of mortar.

Weighing hopper

Description

The weighing bin consists of hopper, steel frame, and load cell (the lower part of the weighing bin is equipped with a discharge screw). The weighing bin is widely used in various mortar lines to weigh ingredients such as cement, sand, fly ash, light calcium, and heavy calcium. It has the advantages of fast batching speed, high measurement accuracy, strong versatility, and can handle various bulk materials.