Vertical dry mortar production line CRL-1

Product Detail

Introduction

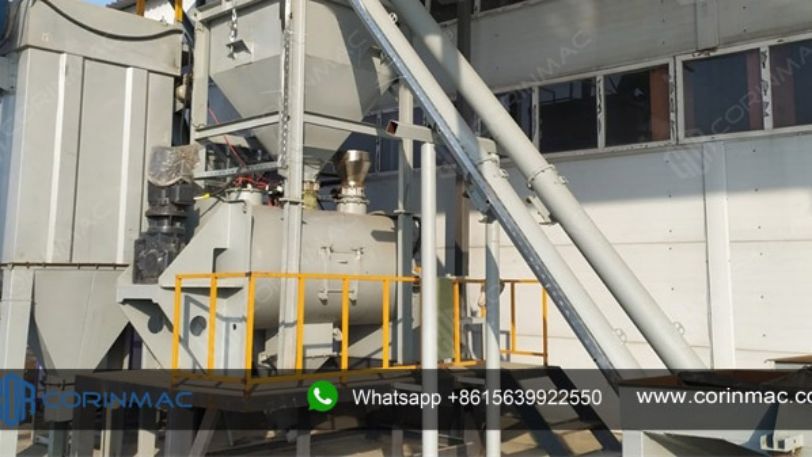

Vertical dry mortar production line

Vertical mortar production line CRL series, also known as standard mortar production line, is a complete set of equipment to batching finished sand, cementitious materials (cement, gypsum, etc.), various additives and other raw materials according to a specific recipe, mix with a mixer, and mechanically packing the obtained dry powder mortar, including raw material storage silo, screw conveyor, weighing hopper, additive batching system, bucket elevator, pre-mixed hopper, mixer, packaging machine, dust collectors and control system.

The name of the vertical mortar production line comes from its vertical structure. The pre-mixed hopper, the additive batching system, the mixer and the packaging machine are arranged on the steel structure platform from top to bottom, which can be divided into single-floor or multi-floors structure.

Mortar production lines will vary greatly due to differences in capacity requirements, technical performance, equipment composition and degree of automation. The entire production line scheme can be customized according to the customer's site and budget.

CRL-1 series production line includes:

• Manual feed hopper for raw materials

• Raw material bucket elevator

• Mixer and packaging machine

• Control cabinet

• Auxiliary equipment

Mixers and packaging machines

Single shaft plough share mixer

The technology of the plough share mixer is mainly from Germany, and it is a mixer commonly used in large-scale dry powder mortar production lines. The plough share mixer is mainly composed of an outer cylinder, a main shaft, plough shares, and plough share handles. The rotation of the main shaft drives the plowshare-like blades to rotate at a high speed to drive the material to move rapidly in both directions, so as to achieve the purpose of mixing. The stirring speed is fast, and a flying knife is installed on the wall of the cylinder, which can quickly disperse the material, so that the mixing is more uniform and fast, and the mixing quality is high.

Single shaft plough share mixer(big discharge door)

Single shaft plough share mixer(super high speed)

Product hopper

The finished product hopper is a closed silo made of alloy steel plates for storing mixed products. The top of the silo is equipped with a feeding port, a breathing system and a dust collection device. The cone part of the silo is equipped with a pneumatic vibrator and an arch breaking device to prevent the material from being blocked in the hopper.

Valve bag packing machine

According to the requirements of different customers, we can provide three different types of packing machine, impeller type, air blowing type and air floating type for your choice. The weighing module is the core part of the valve bag packing machine. The weighing sensor, weighing controller and electronic control components used in our packaging machine are all first-class brands, with large measuring range, high precision, sensitive feedback, and the weighing error could be ±0.2 %, can fully meet your requirements.

Control cabinet

The equipment listed above is the basic type of this type of production line.

If it is necessary to reduce dust in the workplace and improve the working environment of workers, a small pulse dust collector can be installed.

In short, we can do different program designs and configurations according to your requirements.

Company Profile

CORINMAC-Cooperation& Win-Win, this is the origin of our team name.

This is also our operating principle: through teamwork and cooperation with customers, create value for individuals and customers, and then realize the value of our company.

Since its founding in 2006, CORINMAC has been a pragmatic and efficient company. We are committed to finding the best solutions for our customers by providing high-quality equipment and high-level production lines to help customers achieve growth and breakthroughs, because we deeply understand that customer's success is our success!

Customer visits

Welcome to CORINMAC. CORINMAC's professional team offers you comprehensive services. No matter which country you come from, we can provide you with the most considerate support. We have extensive experience in dry mortar manufacturing plants. We will share our experience with our customers and help them start their own business and make money. We thank our customers for their trust and support!

User Feedback

Our products have won a good reputation and recognition in more than 40 countries, including the United States, Russia, Kazakhstan, Kyrgyzstan, Uzbekistan, Turkmenistan, Mongolia, Vietnam, Malaysia, Saudi Arabia, the United Arab Emirates, Qatar, Peru, Chile, Kenya, Libya, Guinea, Tunisia, etc.

Installation steps guidance

Drawing

Our products

Recommended products

Rotary dryer with low energy consumption and hi...

Features and Advantages:

1. According to the different materials to be dried, the suitable rotate cylinder structure could be selected.

2. Smooth and reliable operation.

3. Different heat sources are available: natural gas, diesel, coal, biomass particles, etc.

4. Intelligent temperature control.

High precision additives weighing system

Features:

1. High weighing accuracy: using high-precision bellows load cell,

2. Convenient operation: Fully automatic operation, feeding, weighing and conveying are completed with one key. After being connected with the production line control system, it is synchronized with the production operation without manual intervention.

see more

Impulse bags dust collector with high purificat...

Features:

1. High purification efficiency and large processing capacity.

2. Stable performance, long service life of the filter bag and easy operation.

3. Strong cleaning ability, high dust removal efficiency and low emission concentration.

4. Low energy consumption, reliable and stable operation.

see more

Single shaft plough share mixer

Features:

1. The plough share head has a wear-resistant coating, which has the characteristics of high wear resistance and long service life.

2. Fly cutters be installed on the wall of the mixer tank, which can quickly disperse the material and make the mixing more uniform and fast.

3. According to different material s and different mixing requirements, the mixing method of the plough share mixer can be regulated, such as mixing time, power, speed, etc., to fully ensure the mixing requirements.

4. High production efficiency and high mixing precision.

Simple dry mortar production line CRM2

Capacity: 1-3TPH; 3-5TPH; 5-10TPH

Features and Advantages:

1. Compact structure, small footprint.

2. Equipped with a ton bag unloading machine to process raw materials and reduce the work intensity of workers.

3. Use the weighing hopper to automatically batch ingredients to improve production efficiency.

4. The whole line can realize automatic control.

Three cylinder rotary dryer with high heat effi...

Features:

1. The overall size of the dryer is reduced by more than 30% compared to ordinary single-cylinder rotary dryers, thereby reducing external heat loss.

2. The thermal efficiency of the self-insulating dryer is as high as 80% (compared to only 35% for the ordinary rotary dryer), and the thermal efficiency is 45% higher.

3. Due to the compact installation, the floor space is reduced by 50%, and the infrastructure cost is reduced by 60%

4. The temperature of the finished product after drying is about 60-70 degrees, so that it does not need an additional cooler for cooling.