Vibrating screen with high screening efficiency and stable operation

Product Detail

Vibrating screen introduction

The dry sand screening machine can be divided into three types: linear vibration type, cylindrical type and swing type. Without special requirements, we are equipped with a linear vibration type screening machine in this production line. The screen box of the screening machine has a fully sealed structure, which effectively reduces the dust generated during the working process. Sieve box side plates, power transmission plates and other components are high-quality alloy steel plates, with high yield strength and long service life. The exciting force of this machine is provided by a new type of special vibration motor. The exciting force can be adjusted by adjusting the eccentric block. The number of layers of the screen can be set to 1-3, and a stretch ball is installed between the screens of each layer to prevent the screen from clogging and improve the screening efficiency. The linear vibratory screening machine has the advantages of simple structure, energy saving and high efficiency, small area cover and low maintenance cost. It is an ideal equipment for dry sand screening.

Working principle

The material enters the sieve box through the feeding port, and is driven by two vibrating motors to generate the exciting force to throw the material upward. At the same time, it moves forward in a straight line, and screens a variety of materials with different particle sizes through a multilayer screen, and discharge from the respective outlet. The machine has the characteristics of simple structure, energy saving and high efficiency, and fully enclosed structure without dust overflow.

After drying, the finished sand (water content is generally below 0.5%) enters the vibrating screen, which can be sieved into different particle sizes and discharged from the respective discharge ports according to the requirements. Usually, the size of the screen mesh is 0.63mm, 1.2mm and 2.0mm, the specific mesh size is selected and determined according to actual needs.

All-steel screen frame, unique screen reinforcement technology, easy to replace the screen.

Contains rubber elastic balls, which can automatically clear the screen blockage.

Company Profile

CORINMAC-Cooperation& Win-Win, this is the origin of our team name.

This is also our operating principle: through teamwork and cooperation with customers, create value for individuals and customers, and then realize the value of our company.

Since its founding in 2006, CORINMAC has been a pragmatic and efficient company. We are committed to finding the best solutions for our customers by providing high-quality equipment and high-level production lines to help customers achieve growth and breakthroughs, because we deeply understand that customer's success is our success!

Customer visits

Welcome to CORINMAC. CORINMAC's professional team offers you comprehensive services. No matter which country you come from, we can provide you with the most considerate support. We have extensive experience in dry mortar manufacturing plants. We will share our experience with our customers and help them start their own business and make money. We thank our customers for their trust and support!

Customer feedback

Our products have won a good reputation and recognition in more than 40 countries, including the United States, Russia, Kazakhstan, Kyrgyzstan, Uzbekistan, Turkmenistan, Mongolia, Vietnam, Malaysia, Saudi Arabia, the United Arab Emirates, Qatar, Peru, Chile, Kenya, Libya, Guinea, Tunisia, etc.

Installation steps guidance

Drawing

Our products

Recommended products

Rotary dryer with low energy consumption and hi...

Features and Advantages:

1. According to the different materials to be dried, the suitable rotate cylinder structure could be selected.

2. Smooth and reliable operation.

3. Different heat sources are available: natural gas, diesel, coal, biomass particles, etc.

4. Intelligent temperature control.

Efficient and non-polluting Raymond Mill

Pressurizing device with high pressure spring can improve the grinding pressure of roller, which makes efficiency improved by 10%-20%. And the sealing performance and dust removal effect is pretty good.

Capacity: 0,5-3TPH; 2.1-5.6 TPH; 2.5-9.5 TPH; 6-13 TPH; 13-22 TPH.

Applications: Cement, Coal, power plant desulfurization, metallurgy, chemical industry, non-metallic mineral, construction material, ceramics.

see more

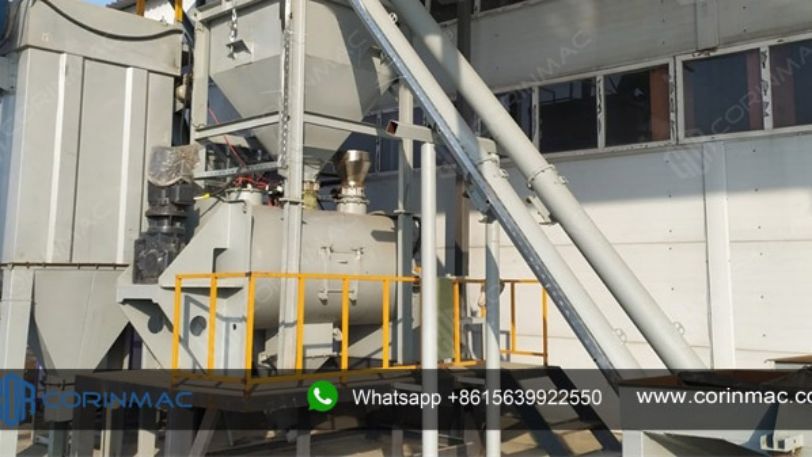

Vertical dry mortar production line CRL-2

Capacity: 5-10TPH; 10-15TPH; 15-20TPH

see more

Stable operation and large conveying capacity b...

Bucket elevator is a widely used vertical conveying equipment. It is used for vertical conveying of powder, granular and bulk materials, as well as highly abrasive materials, such as cement, sand, soil coal, sand, etc. The material temperature is generally below 250 °C, and the lifting height can reach 50 meters.

Conveying capacity: 10-450m³/h

Scope of application: and widely used in building materials, electric power, metallurgy, machinery, chemical industry, mining and other industries.

see more

Small bags packing machine with high precision

Capacity: 10-35 bags per minute; 100-5000g per bag

Features and Advantages:

- 1. Fast packaging and wide application

- 2. High degree of automation

- 3. High packaging precision

- 4. Excellent environmental indicators and non-standard customization

Splicable and stable sheet silo

Features:

1. The diameter of the silo body can be arbitrarily designed according to the needs.

2. Large storage capacity, generally 100-500 tons.

3. The silo body can be disassembled for transportation and assembled on site. Shipping costs are greatly reduced, and one container can hold multiple silos.

see more