Splicable and stable sheet silo

Product Detail

Silo for cement, sand, lime, etc.

Sheet cement silo is a new type of silo body, also called split cement silo (split cement tank). All parts of this type of silo are completed by machining, which gets rid of the defects of roughness and limited conditions caused by manual welding and gas cutting caused by traditional on-site production. It has beautiful appearance, short production period, convenient installation, and centralized transportation. After use, it can be transferred and reused, and it is not affected by the site conditions of the construction site.

Loading of cement into the silo is carried out via a pneumatic cement pipeline. To prevent material hanging and ensure uninterrupted unloading, an aeration system is installed in the lower (conical) part of the silo.

The supply of cement from the silo is carried out mainly by a screw conveyor.

To control the level of material in the silos, high and low level gauges are installed on the silo body. Also, the silos are equipped with filters with a system of impulse blowing of filter elements with compressed air, which has both remote and local control. The cartridge filter is installed on the upper platform of the silo, and serves to clean the dusty air escaping from the silo under the influence of excess pressure when loading cement.

Company Profile

CORINMAC-Cooperation& Win-Win, this is the origin of our team name.

This is also our operating principle: through teamwork and cooperation with customers, create value for individuals and customers, and then realize the value of our company.

Since its founding in 2006, CORINMAC has been a pragmatic and efficient company. We are committed to finding the best solutions for our customers by providing high-quality equipment and high-level production lines to help customers achieve growth and breakthroughs, because we deeply understand that customer's success is our success!

Customer visits

Welcome to CORINMAC. CORINMAC's professional team offers you comprehensive services. No matter which country you come from, we can provide you with the most considerate support. We have extensive experience in dry mortar manufacturing plants. We will share our experience with our customers and help them start their own business and make money. We thank our customers for their trust and support!

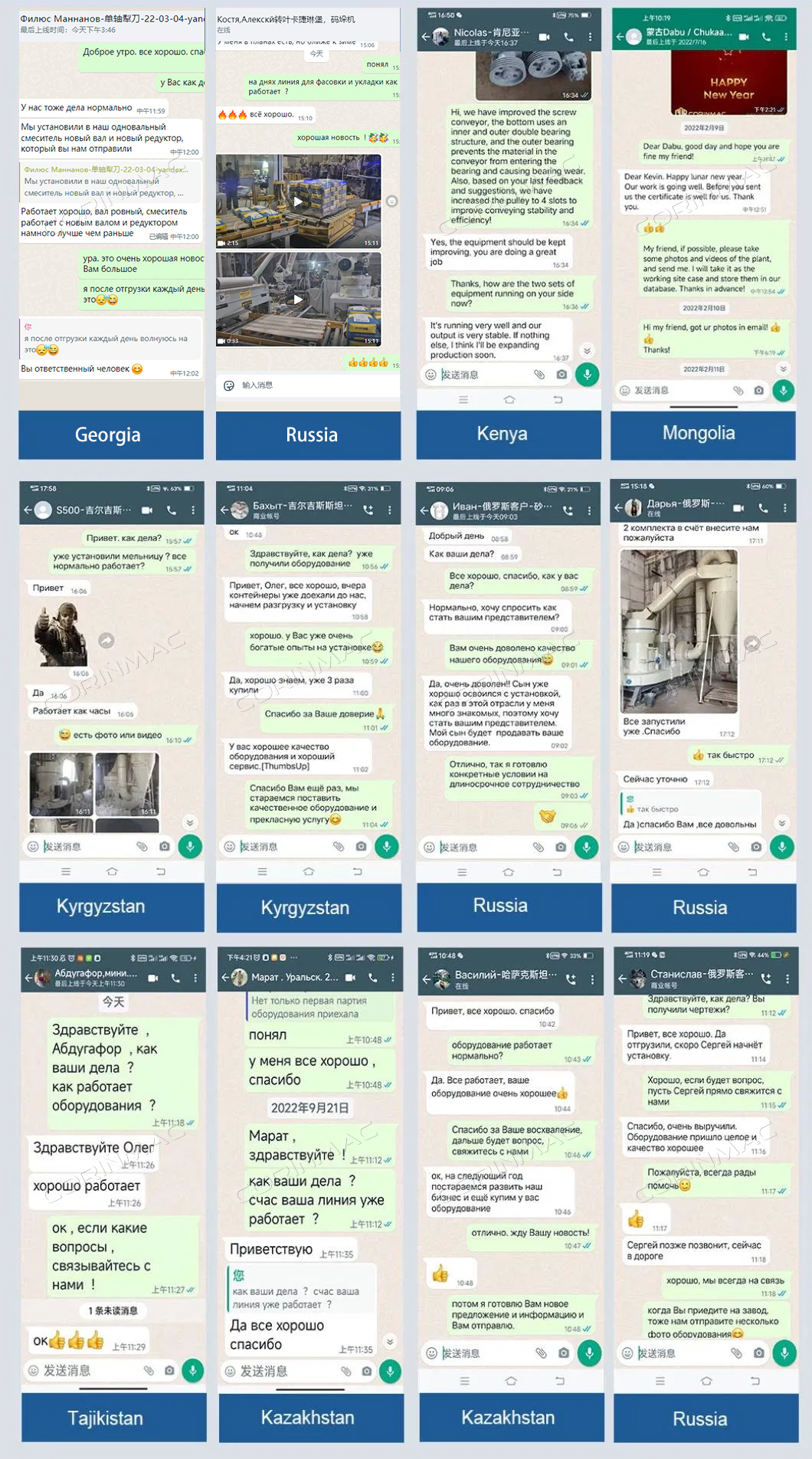

Customer feedback

Our products have won a good reputation and recognition in more than 40 countries, including the United States, Russia, Kazakhstan, Kyrgyzstan, Uzbekistan, Turkmenistan, Mongolia, Vietnam, Malaysia, Saudi Arabia, the United Arab Emirates, Qatar, Peru, Chile, Kenya, Libya, Guinea, Tunisia, etc.

Installation steps guidance

Drawing

Our products

Recommended products

Tower type dry mortar production line

Capacity: 10-15TPH; 15-20TPH; 20-30TPH; 30-40TPH; 50-60TPH

Features and Advantages:

1. Low energy consumption and high production efficiency.

2. Less waste of raw materials, no dust pollution, and low failure rate.

3. And because of the structure of the raw material silos, the production line occupies 1/3 area of the flat production line.

Impulse bags dust collector with high purificat...

Features:

1. High purification efficiency and large processing capacity.

2. Stable performance, long service life of the filter bag and easy operation.

3. Strong cleaning ability, high dust removal efficiency and low emission concentration.

4. Low energy consumption, reliable and stable operation.

see more

Durable and smooth-running belt feeder

Features:

The belt feeder is equipped with a variable frequency speed regulating motor, and the feeding speed can be adjusted arbitrarily to achieve the best drying effect ore other requirement.

It adopts skirt conveyor belt to prevent material leakage.

see more

Fast palletizing speed and stable High Position...

Capacity: 500~1200 bags per hour

Features & Advantages:

- 1. Fast palletizing speed, up to 1200 bags/hour

- 2. The palletizing process is fully automatic

- 3. Arbitrary palletizing can be realized, which is suitable for the characteristics of many bag types and various coding types

- 4. Low power consumption, beautiful stacking shape, saving operating costs

Vertical dry mortar production line CRL-2

Capacity: 5-10TPH; 10-15TPH; 15-20TPH

see more

Vertical dry mortar production line CRL-H

Capacity: 5-10TPH; 10-15TPH; 15-20TPH

see more